CCTV News: Intelligent manufacturing engineering and technical personnel are a new profession that was included in the National Occupational Classification Ceremony in 2020. This craftsman from a great country is an outstanding representative of this profession. He deeply integrates the new generation of information technology, artificial intelligence, high-end equipment manufacturing and the aerospace industry to accelerate the iteration and upgrading of CNC processing technology. He is Liu Zheng, who has just won the honorary title of National Model Worker.

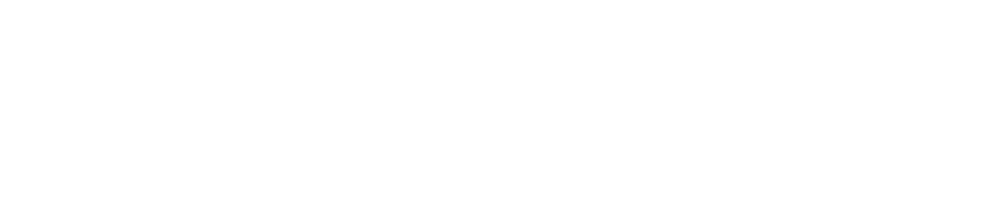

The Long March 2F carrier rocket, this is the only active manned carrier rocket in my country. The safety assessment value reaches the limit index of 0.99996, and it has become the safest manned rocket in the world with a 100% launch success rate.

Liu Zheng, chief craftsman of the First Academy of China Aerospace Science and Technology Corporation, introduced that although the appearance of the Chang Er F Rocket has not changed much, it has actually been upgrading. They made every part to the extreme to ensure that the final rocket was launched foolproof.

Liu Zheng is a craftsman of the China Academy of Launch Vehicle Technology. His job is to design and develop new technologies and equipment to solve the pain points and difficulties in the processing of aerospace parts. The job he is engaged in is a new profession recognized by the Ministry of Human Resources and Social Security - an intelligent manufacturing engineering technician.

Liu Zheng introduced that they can design CNC machine tools based on the overall process needs of the product, so that the manufacturing processability is better, the cost is lower and the efficiency is higher.

In the field of aerospace manufacturing, Liu Zheng has many labels, such as "the most beautiful military worker", "CNC expert", "national model worker", etc. However, when he first went to college, he was like most young people, and was full of confusion about the future. At this moment, a sentence from Liu Baicheng, an academician of the Chinese Academy of Engineering, pointed out the direction for him.

Liu Zheng introduced that he said this: "As a student of the Department of Mechanics of Tsinghua University, it is your responsibility to revitalize China's manufacturing industry." This direction is a goal that can be fought for for a lifetime.

In 2005, Liu Zheng, who held the diploma of the Department of Mechanical Engineering at Tsinghua University and held the ideal of revitalizing China's manufacturing industry, resolutely entered the first-line workshop of aerospace manufacturing. At that time, China only had single-digit space launches, and many rocket manufacturing required manual methods.

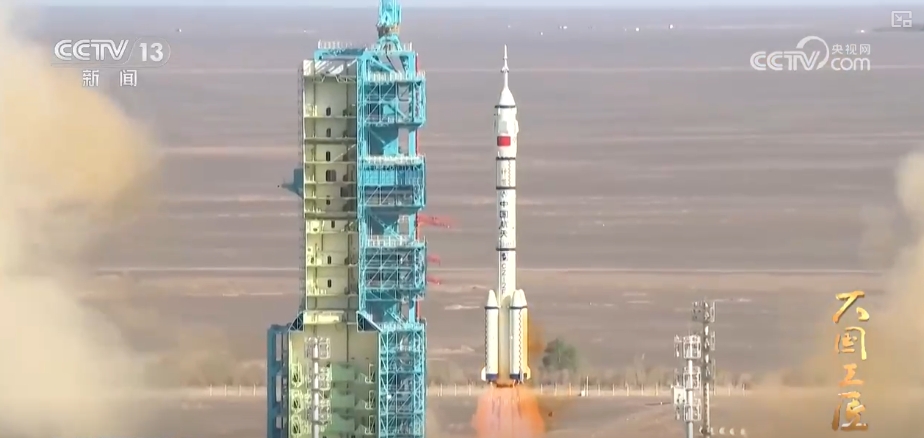

The rocket's cabin is one of the most important components of the rocket. In order to install as much fuel as possible, the rocket itself must be light enough. Therefore, the precise processing of rocket thin walls has always been a problem that restricts rocket production efficiency and accuracy.

The processing of thin walls is like carving on an egg shell. It is too thin and the bearing capacity is insufficient and too thick. The weight of the rocket increases, and it wastes transportation capacity. Traditional processing methods require manual measurement of wall thickness and then manual compensation until the standards are met. Can the machine be automatically completed? Liu Zheng began to conduct a lot of research on the front line.

Faced with this thing that no one had done before, Liu Zheng began a bold attempt. More than a dozen different clamping schemes and hundreds of experiments, however, the results are not ideal.

Continuous failure did not make Liu Zheng lose confidence, but instead inspired his fighting spirit, and his way of decompression was to play basketball.

Countless failures finally ushered in success. Liu Zheng developed a processing plan for automatic measurement and compensation, directly installing the measuring head on the machine tool to guide the machine tool to automatically compensate, and there is no need for manual operation throughout the process. Before the implementation of the plan, many people were also suspicious, but as soon as the test results came out, everyone was convinced.

The success of automatic measurement compensation technology has enabled my country to achieve a 10% % wall thickness of a large-scale shell section for the first time, and won the Gold Award for the Nuremberg International Invention Exhibition in Germany.

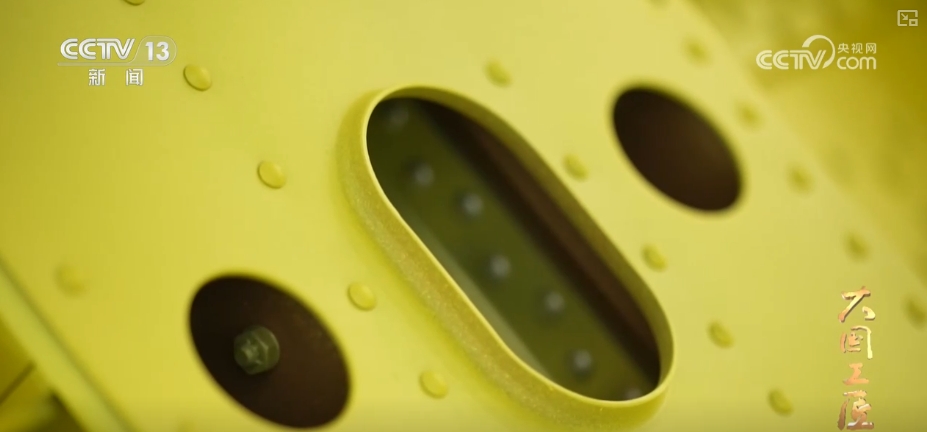

Now, Liu Zheng, who loves to fight and innovate, is developing a new generation of processing equipment. This mobile machining robot is like a mobile machine tool, which will completely change the machining difficulties of large aerospace components.

Over the past 20 years, discovering and solving problems has always been the whole of Liu Zheng's work. Under his leadership, the team achieved China's first 100% five-axis CNC machining of symmetrical spacecraft, overcome the problem of processing the inner wall of the nozzle of a large-thrust hydrogen-oxygen engine, etc., undertakes 37 major projects such as national ministries and commissions, and obtained 12 national patents.

Liu Zheng said that there is a "fight" in his name, and their work must be foolproof, because there is no mistake. His word "fight" is not only his working state, but also a spiritual portrayal of all aerospace people. Their dream is the sea of stars, so we must continue to fight as always!