CCTV News: At the beginning of the New Year, China First Media, located in Qiqihar, an old industrial base in Northeast China, has begun to work hard. A sintering furnace that is more than 20 meters high is burning, and a nuclear power equipment weighing 700 tons has been released. Let’s follow CCTV reporters on site to experience this “national weapon”.

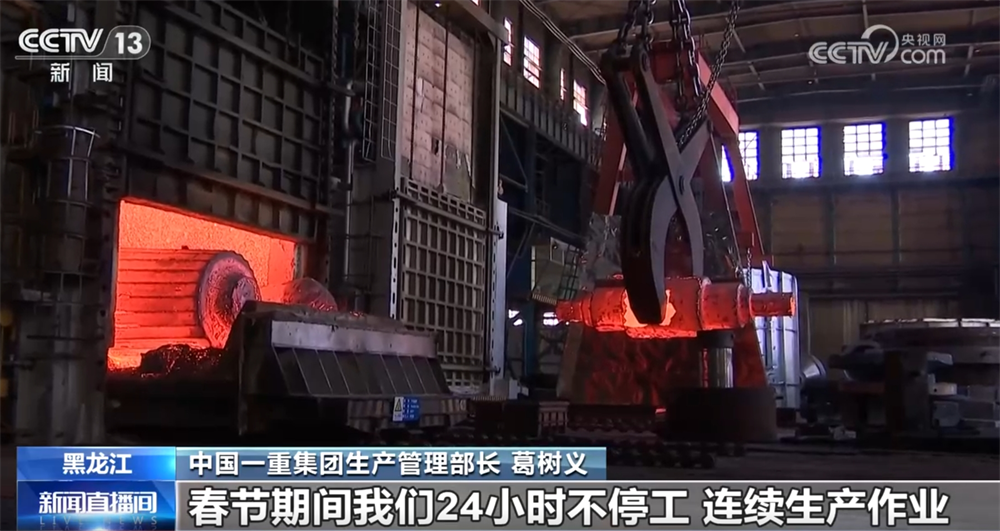

In the forging workshop of major equipment, although there is a biting cold wind of minus 20 to 30 degrees Celsius outside the window, the workshop is full of busy and busy scenes. Behind the reporter, the world's largest mass-produced steel ingot forgings is slowly coming out. Its temperature reaches more than 1,200 degrees Celsius. The reporter can feel its rolling heat waves through twenty or thirty meters. It is mainly used to manufacture the rotor, the most critical component of the nuclear power unit. This is also the first nuclear power rotor casting they released this year.

This behemoth is equivalent to the weight of 170 elephants. The difficulty in making it lies in the overall forging. It requires the largest steel ingot, the largest blank weight, and the largest cross-sectional size, and the core technical requirements are very strict. Just like a room of 10 square meters, there is no defect as big as millet grains. The heating process before forging alone requires a high temperature of more than 1,200 degrees Celsius to burn for 3 days. After the oven is released, it must be subjected to repeated forging and pressing of a 15,000-ton giant forging press like kneading dough to ensure that the density of the internal and external materials meets the requirements.

Wang Lizhong, director of the Foundry Crafts Office of the First Re-cast Forged Steel Division of China, said: "Its size is not only reflected in the weight and shape, but more importantly in the internal quality. Just like when we knead dough, it is more difficult to knead into uniform materials from the inside out. Now China, First Re-cast has fully mastered this technology."

Currently, only two companies in the world can produce such a huge nuclear power equipment, and breakthroughs in key technologies have also ushered in the market's recognition.

Ge Shuyi, director of the production management of China First Heavy Group, said: "This product is currently in short supply, and our orders have been scheduled to 2027. In the new year, we have very full orders in hand. During the Spring Festival, we have been working continuously forged 24 hours a day, and we have produced more than 3,000 tons of forgings since February, setting a record high."

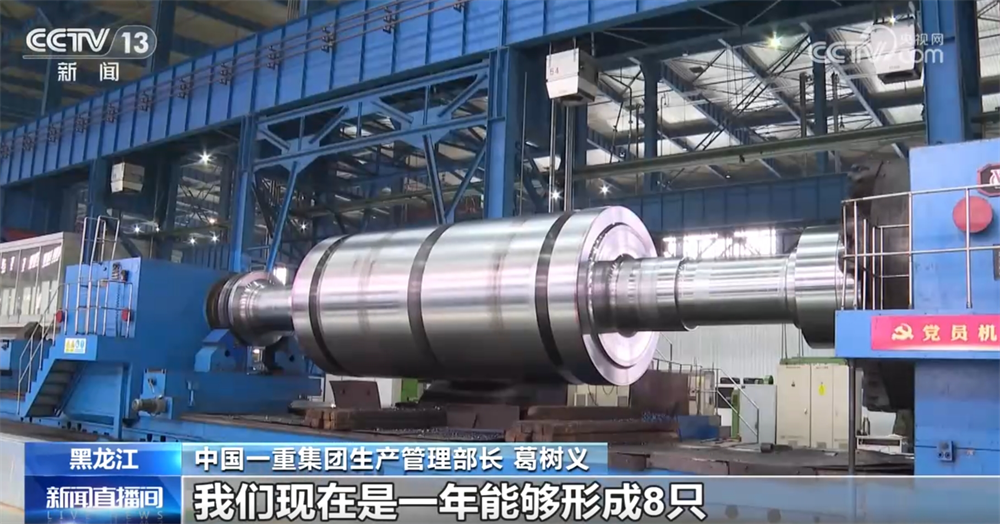

Through management improvement and process optimization, the product forging cycle has been shortened from the original 45 days to about 30 days, the efficiency has been increased by 30%, and the cost has been greatly reduced.

Ge Shuyi said: "What I am in my hand is the miniature model of the rotor, and it looks like this after the rotor is processed. What we are processing on our machine tool is a blank, and we will turn to here for rough processing. The processing capacity of this product is now 8 in a year, which is the highest in the world."